Conduit Fittings Demystified: A Deep Dive into Electrical Conduit, Wire, and Cable Management

By Amelie Falconer / February 9, 2024 / No Comments / Electrical Supplies

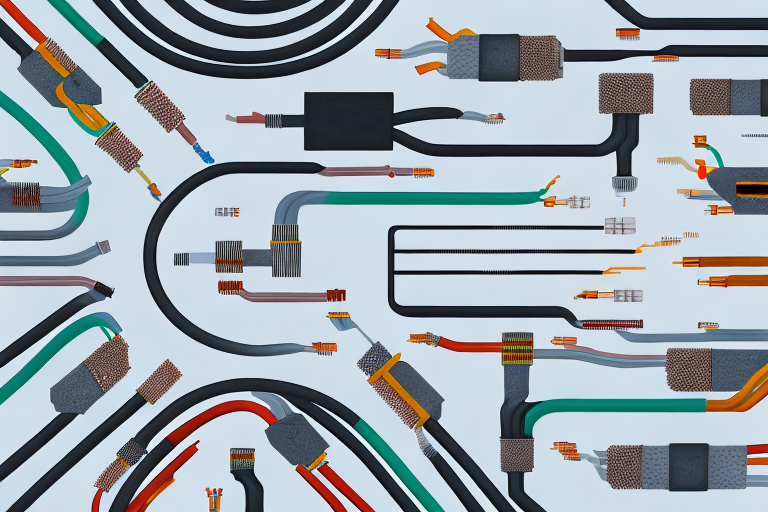

In the world of electrical installations, conduit fittings play a crucial role in ensuring the proper management of wires and cables. Understanding the basics of conduit fittings, as well as the types of electrical conduits available, is essential for any electrician or DIY enthusiast. Additionally, knowing how to troubleshoot common conduit fitting problems and prioritize safety during installations is vital. In this article, we will delve into all these aspects to demystify conduit fittings and provide a comprehensive guide to electrical conduit, wire, and cable management.

Understanding the Basics of Conduit Fittings

Before we dive into the specifics, let’s first understand what conduit fittings are and why they are important in electrical supplies installations.

Conduit fittings play a crucial role in electrical installations, ensuring the safety and efficiency of the system. They are components that connect and secure electrical conduits to electrical junction boxes, enclosures, and other conduit fittings. By doing so, they provide a means to protect and route electrical wires and cables, ensuring a safe and organized installation.

What are Conduit Fittings?

Conduit fittings, also known as electrical fittings, are devices designed to connect and secure electrical conduit. They come in various shapes, sizes, and materials to accommodate different installation requirements. Some common types of conduit fittings include connectors, couplings, elbows, and bushings.

Connectors are used to join two pieces of conduit together, providing a secure and reliable connection. Couplings, on the other hand, are used to connect two conduit sections of the same size. Elbows, as the name suggests, are fittings that allow the conduit to change direction, ensuring a smooth and efficient routing of wires. Bushings, on the other hand, are used to protect wires from sharp edges and provide additional support.

Importance of Conduit Fittings in Electrical Installations

Conduit fittings are essential for a variety of reasons. Firstly, they protect wires and cables from physical damage, moisture, and corrosion, extending their lifespan. The conduit itself provides a protective barrier, shielding the wires from external elements, while the fittings ensure a secure and watertight connection, preventing moisture from seeping in.

Moreover, conduit fittings help maintain proper grounding and bonding, reducing electrical hazards. Grounding is crucial in electrical systems as it provides a path for electrical faults to safely discharge, preventing electrical shocks and fires. Conduit fittings, when properly installed, ensure a continuous grounding path, enhancing the safety of the installation.

Additionally, fittings facilitate easy access for maintenance and future expansions or modifications. In electrical installations, it is common for changes to be made over time, such as adding new circuits or replacing damaged wires. Conduit fittings allow for easy disconnection and reconnection, making these modifications simpler and less time-consuming. Visit https://lawnmastersky.com/manly-florist-where-floral-creativity-meets-your-desires/ to read about Manly Florist: Where Floral Creativity Meets Your Desires.

Furthermore, conduit fittings contribute to the overall aesthetics of the installation. With a wide range of fittings available, installers can choose fittings that complement the design and style of the building, creating a visually appealing and professional-looking electrical system.

In conclusion, conduit fittings are not just simple components that connect conduit and junction boxes. They play a vital role in protecting wires, ensuring proper grounding, facilitating maintenance and modifications, and enhancing the overall aesthetics of electrical installations. Understanding the basics of conduit fittings is essential for anyone involved in electrical work, as it ensures a safe, efficient, and reliable electrical system.

Types of Electrical Conduits

Now that we have a good understanding of conduit fittings, let’s explore the different types of electrical conduits commonly used in installations.

Rigid Metal Conduits (RMC)

Rigid Metal Conduits, often referred to as RMC, are the most durable and robust option. Made of galvanized steel, RMC can withstand harsh environmental conditions and offer excellent protection to wires and cables.

These conduits are commonly used in industrial settings where durability and strength are crucial. They are designed to provide maximum protection to electrical wiring, ensuring the safety and reliability of the electrical system. RMC conduits are resistant to corrosion, impact, and fire, making them suitable for both indoor and outdoor applications.

Additionally, RMC conduits have a threaded connection system, which allows for easy installation and secure connections. This feature ensures that the conduits remain firmly in place, even in high-vibration environments.

Electrical Metallic Tubing (EMT)

Electrical Metallic Tubing, or EMT, is a lightweight and cost-effective conduit option. It is made of thin-walled steel and is commonly used in residential and commercial installations.

EMT conduits are known for their versatility and ease of installation. They are often used in applications where flexibility is required, such as in walls, ceilings, and floors. The thin walls of EMT conduits make them easy to bend and shape, allowing for smooth and efficient routing of electrical wires.

In addition to their flexibility, EMT conduits provide excellent protection against physical damage and corrosion. They are also compatible with a wide range of conduit fittings, making them highly adaptable to various electrical installations.

Flexible Conduits

If flexibility is a requirement, flexible conduits are the way to go. Also known as “flex,” these conduits are made of corrugated plastic or metal and are ideal for areas where installation in tight spaces or around corners is necessary.

Flexible conduits offer the advantage of easy maneuverability, allowing for hassle-free installation in challenging environments. They are commonly used in applications where there is a need to accommodate movement or vibration, such as in machinery or outdoor installations.

These conduits come in various materials, including PVC, nylon, and metal, each offering different levels of flexibility and durability. The corrugated design of flexible conduits provides added strength and protection to the enclosed wires, ensuring their longevity and safety.

Furthermore, flexible conduits can be easily cut to the desired length, making them highly customizable for specific installation requirements. They are also resistant to UV rays, chemicals, and moisture, making them suitable for both indoor and outdoor applications.

Wire and Cable Management Essentials

Now that we have covered conduit fittings and the different types of conduits, it’s important to understand how to manage wires and cables effectively within the conduit system.

When it comes to wire management, there are several factors to consider. One of the most important aspects is understanding the different wire types and their applications. There are various wire types available for different applications, including THHN/THWN, NM-B, and SER cables. Each wire type has its own set of characteristics and is designed for specific purposes. For example, THHN/THWN wires are commonly used in residential and commercial buildings for general electrical wiring, while NM-B cables are commonly used for indoor residential applications. Click here to read about Is THHN wire compatible with SolarAPP+.

Choosing the appropriate wire type for your installation is crucial for optimal performance and safety. By understanding the characteristics of each wire type, you can ensure that you are using the right wire for the job. This not only prevents potential electrical hazards but also ensures that your electrical system operates efficiently.

In addition to selecting the right wire type, proper cable management techniques are essential for an organized and efficient electrical installation. Without proper management, wires and cables can become tangled, leading to potential damage and interference. To prevent this, it is important to utilize cable ties, conduits, and cable trays.

Cable ties are a simple yet effective tool for securing and organizing wires and cables. They come in various sizes and materials, allowing you to choose the most suitable option for your specific needs. By bundling and securing wires with cable ties, you can prevent them from becoming tangled and ensure a neat and organized installation.

Conduits are another important component of cable management. They provide a protective enclosure for wires and cables, shielding them from external elements and potential damage. Conduits also help route wires in a structured manner, making it easier to identify and troubleshoot any issues that may arise.

Cable trays are yet another useful tool for cable management. They provide a safe and organized pathway for multiple wires and cables. With cable trays, you can easily route and support wires, ensuring that they are kept away from potential hazards and interference.

By utilizing these cable management techniques, you can ensure that your wires and cables are properly routed and secured within the conduit system. This not only improves the overall aesthetics of the installation but also enhances safety and reduces the risk of electrical issues.

Safety Considerations for Conduit Installations

Safety should always be a top priority when working with electrical conduits and fittings. Paying attention to electrical codes and standards, as well as wearing the right personal protective equipment (PPE), is key to preventing accidents and maintaining a safe working environment.

When it comes to conduit installations, there are several safety considerations that should be taken into account. In addition to following electrical codes and standards, it is important to be aware of potential hazards and take appropriate precautions to mitigate risks.

Electrical Codes and Standards

Electrical codes and standards provide guidelines and regulations for proper conduit installations. Familiarize yourself with these codes, such as the National Electrical Code (NEC), and adhere to them to ensure compliance and safety.

The NEC, for example, covers various aspects of conduit installations, including sizing, grounding, and wiring methods. It provides specific requirements that must be met to ensure the safe installation and operation of electrical conduits.

By following these codes and standards, you can ensure that your conduit installations are done correctly and in accordance with industry best practices. This not only helps prevent accidents but also ensures the longevity and reliability of the electrical system.

Personal Protective Equipment for Conduit Installation

When working with electrical conduits, it is important to wear appropriate PPE, such as safety glasses, gloves, and sturdy footwear. These protective measures minimize the risk of injury from potential electrical shocks, falls, or other hazards.

Safety glasses are essential to protect your eyes from any debris or particles that may be generated during the installation process. Gloves provide a barrier between your hands and any sharp edges or potential electrical currents. Sturdy footwear, preferably with slip-resistant soles, helps prevent slips, trips, and falls in the work area.

In addition to these basic PPE items, it is also important to consider other safety equipment that may be necessary for specific conduit installations. For example, when working in confined spaces, a harness and fall protection equipment may be required to prevent falls and ensure worker safety.

Regular inspection and maintenance of your PPE is crucial to ensure its effectiveness. Any damaged or worn-out equipment should be replaced immediately to maintain a high level of protection.

Remember, safety is a shared responsibility. It is important to communicate and collaborate with your team members to ensure everyone is aware of the safety protocols and procedures. Regular safety meetings and training sessions can help reinforce the importance of safety and keep everyone informed about any updates or changes in safety regulations.

Troubleshooting Common Conduit Fitting Problems

Even with proper installations, issues with conduit fittings may still arise. It is crucial to identify and address these problems promptly to maintain the integrity and safety of the electrical system.

Identifying and Addressing Loose Connections

Loose connections within conduit fittings can lead to intermittent electrical issues or even complete system failure. Regular inspections and tightening of fittings can prevent potential problems and ensure a reliable electrical installation.

Dealing with Corrosion in Conduit Fittings

Corrosion is a common problem in electrical installations, especially in damp or corrosive environments. Using corrosion-resistant conduit fittings and regularly inspecting and replacing corroded components can mitigate this issue and prolong the lifespan of the installation.

By understanding the basics of conduit fittings, familiarizing ourselves with the different types of electrical conduits, and prioritizing safety and troubleshooting techniques, we can demystify the world of electrical conduit, wire, and cable management. Whether you are a professional electrician or a DIY enthusiast, this comprehensive guide will equip you with the knowledge and skills needed to achieve safe, efficient, and reliable electrical installations.